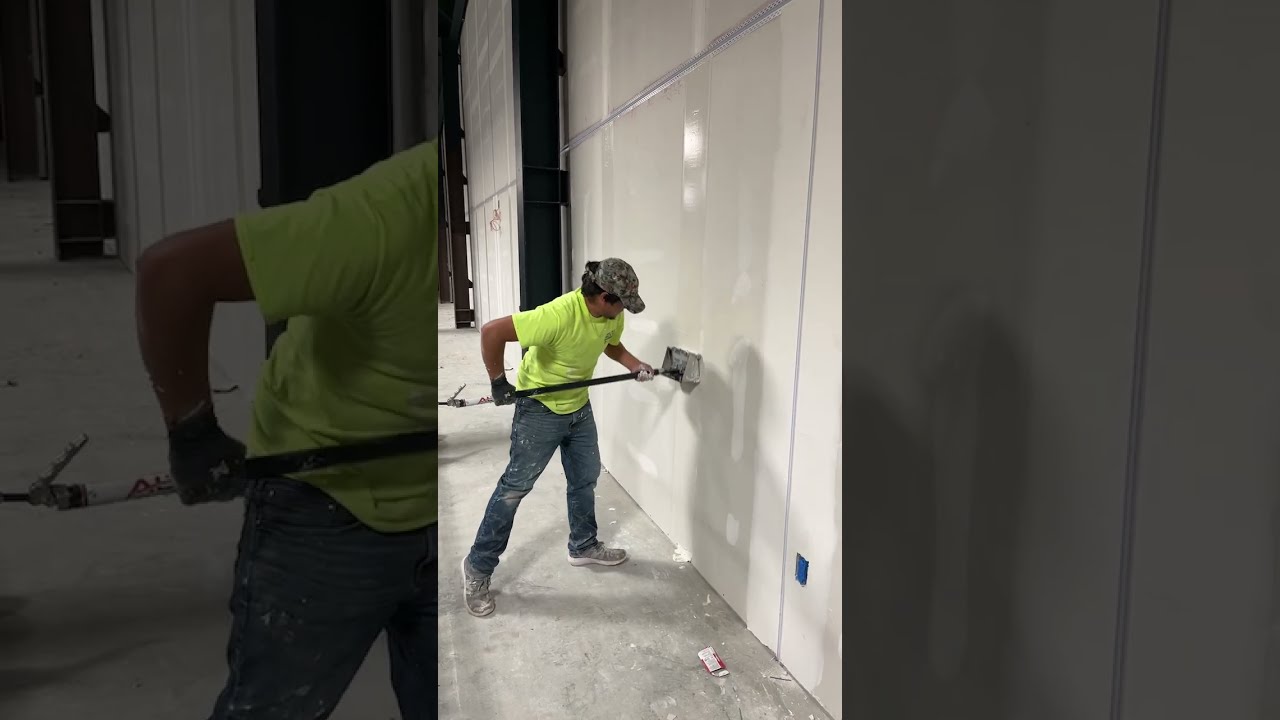

Are you misusing your taping tools daily? It's easy to overlook proper techniques, but misuse compromises quality and damages your tools. Using the wrong tape or applying it too aggressively can lead to unsatisfactory results. Remember to clean your tools after each use to prevent residue buildup and check for dull blades or other wear signs. Storing them correctly and in controlled environments is essential for maintaining their lifespan. If you're aiming for professional results, find tips that can improve your tool usage and performance.

Key Takeaways

- Using the wrong tape for specific applications can lead to poor adhesion and uneven surfaces.Applying tape too aggressively may cause tears and compromise the surface finish.Dull blades can damage tape and tools, resulting in frustrating work and poor results.Exposing tools to extreme temperatures or moisture can degrade their performance and adhesive quality.

Importance of Proper Tool Use

Using the right tools correctly is vital for achieving professional results and preventing costly mistakes. Columbia taping tools are designed for efficiency, but if you misuse them, you'll not only compromise your work quality, but you might also damage the tools. Proper usage starts with understanding their functions and adhering to manufacturer guidelines.

You should also prioritize the maintenance and care of taping tools to prolong their lifespan and guarantee consistent performance. Regularly inspect your tools for wear and tear, and address any issues immediately. Fundamental care techniques for taping tools include cleaning the blades and verifying that moving parts are well-lubricated. This way, you prevent unnecessary wear and maintain precision in your work.

When you treat your tools with respect, you'll notice the difference in your results. Remember, investing time in the proper use and care of your Columbia taping tools pays off in the long run, saving you money and frustration.

Daily Cleaning Practices

Maintaining your Columbia taping tools through daily cleaning practices not only improves their performance but also extends their lifespan. After each use, take a few minutes to clean your tools thoroughly. Start by wiping down any residue or dust with a soft cloth. Pay close attention to the blades and edges, as even small amounts of compound can hinder their functionality.

If you've used your tools with joint compound, rinse them with water immediately after use. This prevents the compound from drying and hardening on the surfaces. For tougher residues, consider using a gentle brush to scrub off any stubborn bits. Make sure you dry your tools completely to avoid rust or corrosion.

It's also important to check for any damage during your cleaning routine. Look for nicks, bent edges, or worn-out parts. Addressing these issues early can save you time and money in the long run.

Storage Techniques

Proper storage of your Columbia taping tools is vital to keep them in top condition and ready for your next project. When you invest time and money in quality tools, you want to verify they last.

Here are four fundamental storage techniques to take into account:

Use a Dedicated Tool Bag: Store your taping tools in a sturdy, padded tool bag. This protects them from dust and damage while keeping everything organized. Hang Them Up: If possible, install a pegboard or hooks in your workspace. Hanging your tools not only saves space but also makes them easily accessible. Keep Away from Moisture: Store your tools in a dry environment. Moisture can lead to rust and deterioration, so avoid damp basements or garages. Label Your Storage Containers: If you use bins or drawers, label them for quick identification. This saves you time and frustration when you need a specific tool.

Implementing these storage techniques will prolong the life of your taping tools, confirming they're always ready for action.

Don't forget to check out Master Building Materials for all your taping tool needs!

Common Misuses to Avoid

Avoiding common misuses of your taping tools can greatly improve their performance and lifespan.

One major mistake is using the wrong tape for the job. Always select the appropriate tape for your specific application; using masking tape on a surface that requires duct tape won't give you the results you need.

Another common error is applying tape too aggressively. You might think that pressing down hard guarantees better adhesion, but it can actually lead to tears or uneven surfaces. Instead, apply even pressure without overdoing it.

Also, don't forget about the cutting technique. Using dull blades or cutting with too much force can damage both the tape and your tools. Always verify your blades are sharp for a clean cut.

Lastly, avoid leaving your tape exposed to extreme temperatures or moisture. This can degrade the adhesive quality and make the tape less effective. Store your taping tools and materials in a controlled environment.

Regular Maintenance Checks

Regular maintenance checks on your taping tools guarantee they perform at their best and last longer. By taking a few moments to inspect and maintain your tools, you can save time and money in the long run.

Here's a quick checklist to help you keep your taping tools in top shape:

Inspect the Blade: Check for nicks or dullness. A sharp blade makes clean cuts and reduces frustration. Clean the Surface: Remove any dust, debris, or dried adhesive from the tool's surface. A clean tool guarantees better adhesion and accuracy. Check the Mechanism: Test the tape advance and locking mechanisms to verify they function smoothly. A faulty mechanism can lead to wasted tape and time. Lubricate Moving Parts: Apply a light lubricant to any moving parts to prevent rust and verify smooth operation.When to Replace Tools

Even with diligent maintenance, there comes a time when you need to recognize when it's better to replace your taping tools rather than trying to salvage them. Signs of wear and tear can include rust, cracks, or parts that no longer function as intended. If you find yourself frequently repairing your tools instead of using them, it might be time to contemplate an upgrade.

Another key indicator is performance. If your taping tools are no longer delivering smooth, even results, that can lead to poor finishes and wasted materials. Don't let stubbornness keep you from achieving quality work.

You should also reflect on the duration of your tools. If they're several years old and you're noticing a decline in performance, investing in new tools can save you time and frustration.

Finally, evaluate whether your current tools meet your needs. As projects evolve, so do tool requirements. If you're taking on different types of jobs, it's wise to invest in specialized tools that improve your efficiency.

When the time comes, check out Master Building Materials for quality replacements that will keep your projects running smoothly.

Frequently Asked Questions

What Materials Are Best for Taping Tools?

For taping tools, you'll want materials like durable plastic, stainless steel, or aluminum. These options guarantee longevity and effectiveness, making your projects smoother and more efficient. Don't forget to choose the right tape to match!

How Can I Tell if My Tape Is Too Old?

To tell if your tape's too old, check for brittleness, discoloration, or difficulty in adhering. If it doesn't stick well or tears easily, it's time to replace it. Always choose fresh, quality tape!

Are There Specific Brands to Avoid for Taping Tools?

When choosing taping tools, avoid brands known for poor durability or inconsistent performance. Research user reviews, and consider reputable brands that professionals trust to guarantee you're getting quality tools that'll last through your projects.

Can I Use Taping Tools for Other Applications?

You can use taping tools for other applications, but be cautious. They're designed for specific tasks, and using them differently might lead to subpar results or damage. Always consider the tool's primary purpose before repurposing it.

What Safety Gear Should I Wear When Using Taping Tools?

When using taping tools, you should wear safety glasses to protect your eyes, gloves to shield your hands, and a dust mask to avoid inhaling any particles. Don't forget sturdy footwear for added protection!

Conclusion

In summary, using your taping tools correctly is key to achieving high-quality results.

By adopting proper techniques, keeping your tools clean, and storing them properly, you'll improve your efficiency and extend their lifespan.

Regular maintenance checks will also help you identify when it's time g.co to replace worn-out tools.

Remember, investing a little time in learning and caring for your taping tools can lead to a significant improvement in your craftsmanship.

So, let's enhance your work together!